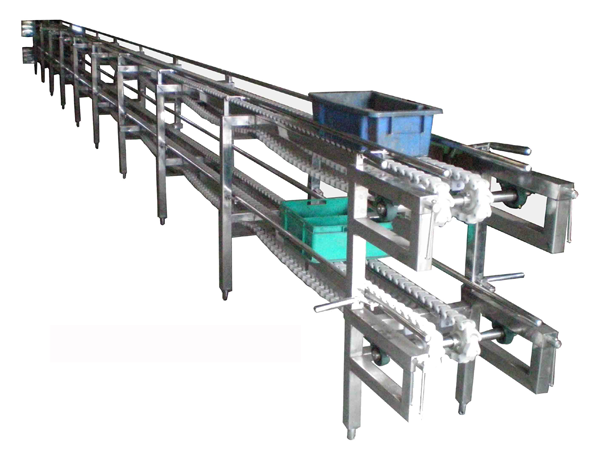

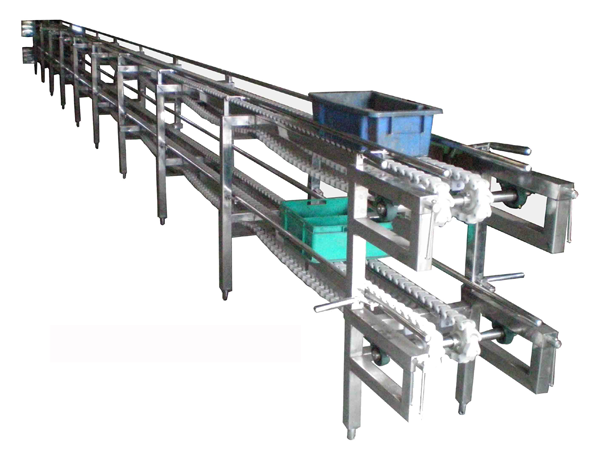

Two - tier Crate Conveyor System is a Double Deck Crate Conveying System, where Crates Can be conveyed in either same directions or opposite directions as per differing Lay outs of Dairies.

Especially meant for Pouch Packing Sections, where washed Crates enter from the Top Deck of Conveyor and Crates are manually picked and filled pouch crates are again reloaded over the Lower Deck and are transported to the Cold Store. Height of the Conveyors are matched with Packing Stations Height and Crate Washer Conveyors Unloading Height as per differing Lay outs of Dairies.

It occupies less space and the amount of Labour required is also reduced.

It can easily handle any amount ( i.e. Capacities ) of Pouch packing machines placed on either side of Conveyor.

Capacities of conveyor varies significantly as per the individual requirement of customers. Generally capacity of Top Deck Conveyor varies from 1000 - 1500 Crates/Hr. and that of Lower Deck is 1500 - 2000 Crates/Hr.

It can be provided with Adjustable Railings as shown in above photo to suit any sized crate.

Individual Drive Units are provided, so that in case of maintenance, any one (1) conveyor can work in absence of other. Drive Units are compact and direct shaft mounted considering space constraints faced by Dairy Industry.